Examining the Benefits of Ductless Fume Hoods for Your Lab Applications

How ductless fume hood technology keeps users safe and offers lab flexibility

Have you ever had or heard these questions or concerns?

“How will we fit a fume hood here?

Is it too far from the exhaust trunk line?

We’re not doing chemistry with obscure chemicals. There should be a simpler way to do this. Sigh.”

We often only think of exhausted fume hoods as being the accepted standard product option for our labs, but should we? Everything has limits, especially technology. We often decide based on a single factor—this is known as the prominence effect—a cognitive bias. But what if that one factor is no longer accurate?

Perhaps we’re not aware of ductless fume hoods, or we haven’t kept up with their technology, or we believe in some of the outdated myths about their safety risks. A best practice is to re-examine our older assumptions and reassess the costs and benefits rather than rule out a viable option based on incomplete knowledge. Your lab’s operations, science, and safety assurances may benefit from ductless technology. By addressing the typical concerns, outdated myths, and current realities of ductless fume hood benefits, you can determine if a ductless option is the best option for your applications.

Ducted versus ductless: use cases, context, and the science

Flexibility

One key benefit to ductless fume hoods is that they provide far greater design flexibility than their ducted counterparts. You’re not restricted to HVAC limitations (e.g., location, supply air capacity, make up air, etc.), it can fit into an existing open space rather than moving everything to accommodate it, and it can be relocated if your lab’s science changes.

Ducted hoods require a connection to the building’s lab exhaust. Since it is constantly exhausting air, that turnover requires sufficient makeup air. Often, labs can’t be in areas that are near the air-supplying capacity for that HVAC zone. Ductless hoods filter out contaminants and recirculate the clean air so there is no need for makeup air.

Sustainability and safety concerns

While we accept the conveniences of exhausting chemicals out the roof stacks, this approach comes with a dark side. We’re relying on that old saying, “The solution to pollution is dilution.” It might seem like a small amount, but it’s often multiplied by continuous exhausting and long-term daily use across many labs—all of which adds up. This approach doesn’t support corporate sustainability or environmental, social, and governance (ESG) goals. It also presents risks, concerns, and challenges for the HVAC workers servicing the hood, valves, ductwork, and for those working on the roof (depending on environmental factors, stack height, etc.). No one wants workers exposed to chemicals as they maintain the building. Ductless hoods don’t exhaust chemicals inside or outside. And with no ductwork, they are much safer and easier to maintain.

Ducted hoods can often handle almost any chemical or reaction within limits. Peroxide formers require specialized equipment. And if your lab uses strong acids or heats them without adequate recovery of the fumes, ductwork can be damaged. There are wide chemistry variations that work well in ductless hoods—very few chemicals aren’t recommended.

Costs

Ducted hoods come with costs—initial capital, ongoing maintenance, and operational costs. The design, connection, and balancing all add to overall expenses. And of course, by exhausting air outside, the energy costs and sustainability concerns are significant. However, initial and ongoing costs for ductless installation, energy, and maintenance are lower.

Addressing safety concerns and myths

In the last decade, some safety, industrial hygienists (IHs), and others have raised concerns about ductless hood technologies. It’s common to not immediately accept something different (or even to initially reject the ideas out of one’s norm). Collaborating as a multi-disciplinary team to discuss all of the currently available technologies, pros and cons, and actual use case in question can result in productive conversations and better decisions. You might find it helpful to invite the principal investigator, safety, engineer, HVAC supervisor, and others to help discuss the variety of perspectives, factors, and threats to value.

It’s important to address these factors proactively. Don’t wait for others to voice their concerns; then it’s a debate with two sides. Instead, show that you have evaluated any concerns. Then it’s a collaborative assessment of costs versus benefits to discuss openly and solve together.

Here are a few examples of what some of the pushback arguments may be, and how ductless fume hoods now have the capabilities and features to prevent the issues raised:

Myth 1: Ductless hoods only remove a small number of contaminants

This is a common comment. Actually, it’s just the opposite. Besides noble gases, carbon filters don’t always retain carbon dioxide, carbon monoxide, and nitrous oxides, which are often easily managed by lab air turnover. The two toxic chemicals not recommended to use with ductless fume hoods are mercury and cyanide simply due to the high level of toxicity and detection limitations, and neither is common in labs.

Myth 2: My EHS team will need to do lots of OSHA air monitoring to prove it’s working properly

OSHA does require some form of objective data to assess potential exposures. Most IHs and EHS collect air samples near the worker’s breathing zone, but that’s not the only method OSHA allows. Other air monitoring, calculations, and scientific approaches are used by OSHA and the regulated community. between updates to a variety of standards (AFNOR, ANSI, ASHRAE, and NFPA) as well as the scientific testing some perform against well-established guidance exposure limits of the American Conference of Governmental Industrial Hygienists Threshold Limit Values (ACGIH TLVs), OSHA’s regulatory requirement for “objective data” is well covered. In fact, continuous monitoring at the filter exhaust of a ductless fume hood ensures no more than one percent of the TLV is ever released back into the lab.

Myth 3: Taking care of the filters is cumbersome (e.g., monitoring, handling, disposing of them)

Because the filters remove chemical vapors, etc. they do need to be disposed of properly over time. Proper disposal of the carbon filters is through incineration as non-hazardous waste as determined by the toxicity characteristic leaching procedure (TCLP) hazardous waste test. The incineration process must also adhere to strict EPA guidelines 40 CFR 264.343, which are performance standards.

Myth 4: We won’t know the filters aren’t removing contaminants properly until it’s too late.

Sensor technology has vastly improved. Some ductless fume hoods now have sensing technologies built-in to send alerts to your phone for exceedances or other issues. Built-in filter redundancy further assures safety in the event of a spill or increased evaporation due to possible changes in your chemical handling This represents an advantage that fume hood exhausts don’t often include.

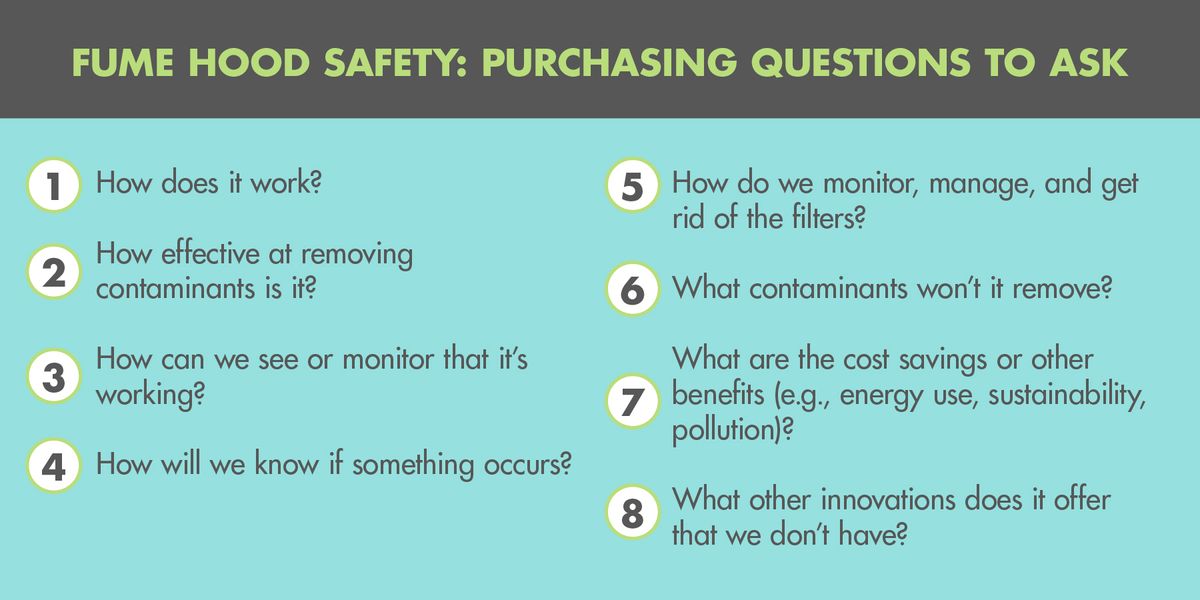

It’s understandable (and necessary) for lab managers and safety professionals to be very diligent in the decisions they make regarding the safety of their staff. It can be difficult to know if equipment or newer technologies are performing as they should to keep staff safe while in use. By knowing all the potential risks and realities, lab managers can be informed to have educated conversations with their vendors and service providers to ensure they are choosing a product that will work for their staff’s scientific needs, be confident of their health and safety, and manage or mitigate lab risks.